Reference: Retrofit production line for contact switches

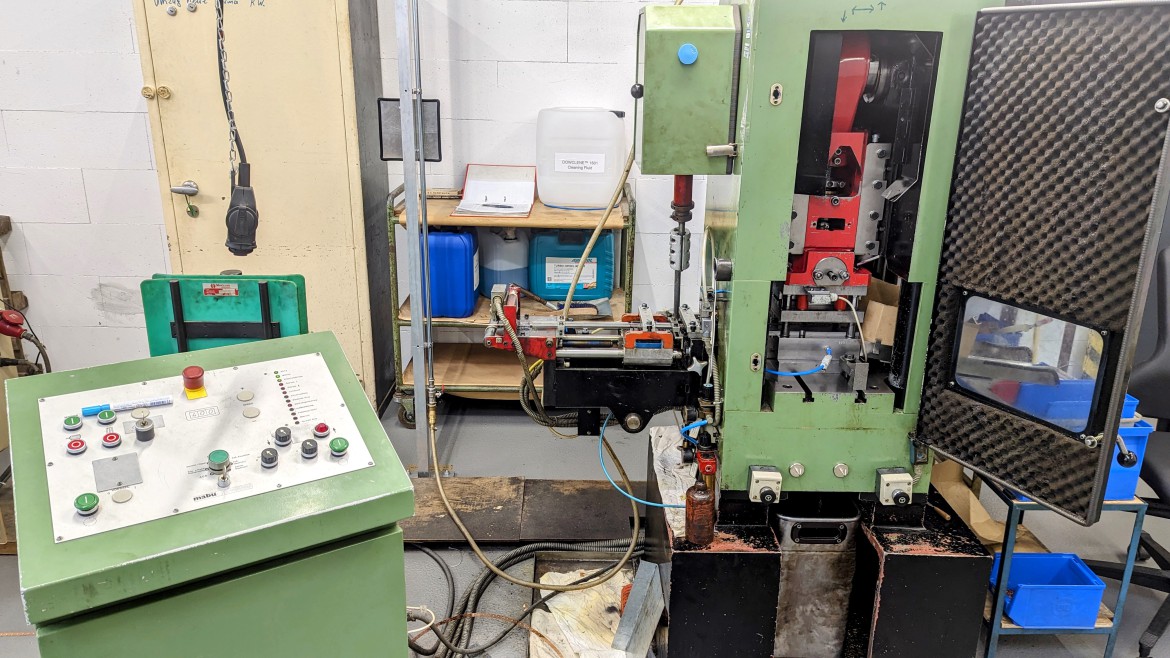

A production line for contact switching pieces (punching-welding line) is to undergo a fundamental retrofit. The aim of the project is to bring the line, which dates back to 1987, up to date with the latest technology. The special feature is that longer shutdowns are not possible. This means that the retrofit must be carried out in parallel with operation.

Eike Kammer, Projektleiter Retrofit

+49 (0) 3375 2131-155

E.Kammer@eaw-relaistechnik.de

Problem Statement

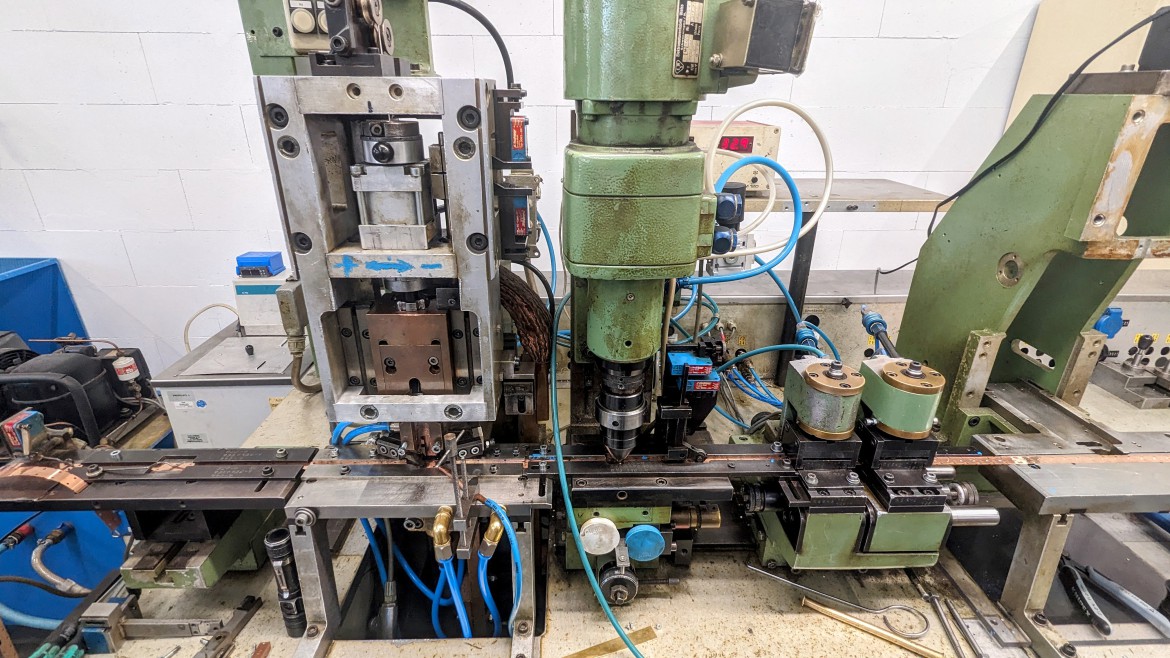

As part of this project, the existing plant will be completely modernized. The main function of the punching-welding line is the production of contact switching pieces for the thermal switch production of the eaw. For this purpose, strips (coils) of different widths and materials are unrolled via a strip reel and fed to a first punch (pre-punch). Pre-punching is followed by the actual machining of the contact switches on the welding table.

Here, switching points made of silver wire are welded onto the workpieces and then tumbled. A second punch (finished punch) completes the machining of the workpieces and removes them from the strip.

The system is essential to produce thermal switches, and irreparable failure, for example of the control technology, must be avoided at all costs. There is no backup here. The utilization of the system and the operating personnel is also quite high, so that a long-term shutdown is out of the question for modernization and pre-production would only be associated with extreme effort.

As in our first retrofit project, this system has various problems due to wear and tear, loss of quality, unassured availability of spare parts and safety risks due to overridden or non-existent safety functions.

The retrofit team develops a concept for how the complete modernization can be implemented: without jeopardizing the production of thermal switches and – soon – handing over to the customer a production line that is practically as good as new, safe and highly available.

Work in progress...

If you are interested in the progress of the project, check back soon. We will periodically update this page and report on our progress.